We carry both the 1.5″ x 3″ and the 1.5″ x 1.5″ aluminum extrusions. The 1.5″ x 3.0″ shape is designed for larger structures where strength is not critical. Applications for 1.5″ x 3.0″L include framing and door tracks. This shape can be used to run air lines or as a pressure or vacuum manifold up to 150 PSI. The 1.5″ x 1.5″ shape was designed for lighter weight and strength requirements than our 1.5″ x 1.5″. Applications include lighter load bearing structures, guarding and light weight frames. In addition to these extrusions, we carry a variety of brackets along <a class="read-more" href="https://sibeautomation.com/parts/aluminum-t-slot-extrusions-brackets-and-fasteners/">[...] Read More</a> ...

Ceramic wire connectors, ideal to connect heaters and other devices where high-temperature protection is required. These large ceramic wire connectors are for wire gauge 22-14. The large ceramic wire connectors are equivalent to the red plastic wire nut. Typical uses include appliances, high powered lighting fixtures, ceiling fans, heaters, plastic extrusion-injection molding barrels, and similar high-temperature applications. They have a maximum working temperature of 1000° Fahrenheit and are specified instead of plastic for applications above 200° Fahrenheit. We also carry large (equivalent to red) and medium (equivalent to yellow). ...

These clamp-down cylinders are used in the clamping frames of vacuum forming machines with pneumatic clamping frames. They fit SIBE Automation, Heartland, ZMD and others. ...

UL Recognized / CSA Certified lead wire We carry wire that operates in the following maximum temperatures 200°C (392°F) 250°C (482°F) 538°C (1000°F) Typical applications include: extrusion machines, heater bands, appliance and fixtures, etc Lead wires are unaffected by flame, fuels, solvents most acids, alkalis and oils and pass IEEE-383 70,000 BTU/HR Flame Test. The standard conductor material is nickel-coated copper. ...

These are efficient, long to medium wavelength infrared panel heaters designed for rugged industrial heating applications requiring excellent uniformity. Operate at surface temperatures up to 1350 F(2.9 micron-peak). 4320 WATTS 240 or 480 Volts Unique black glass/ceramic face material. Highly efficient and effective. Efficiencies exceeding 83% have been proven. Heats up to processing temperatures in about 3-5 minutes. Cools down to “safe” temperatures in about 5-10 minutes. Operating life in excess of 10,000 hours is expected when operated at 80% of rated output. Uniform full heat area. A resistive load can be precisely controlled. Completely field serviceable. Heats all colors <a class="read-more" href="https://sibeautomation.com/parts/infrared-radiant-heaters/">[...] Read More</a> ...

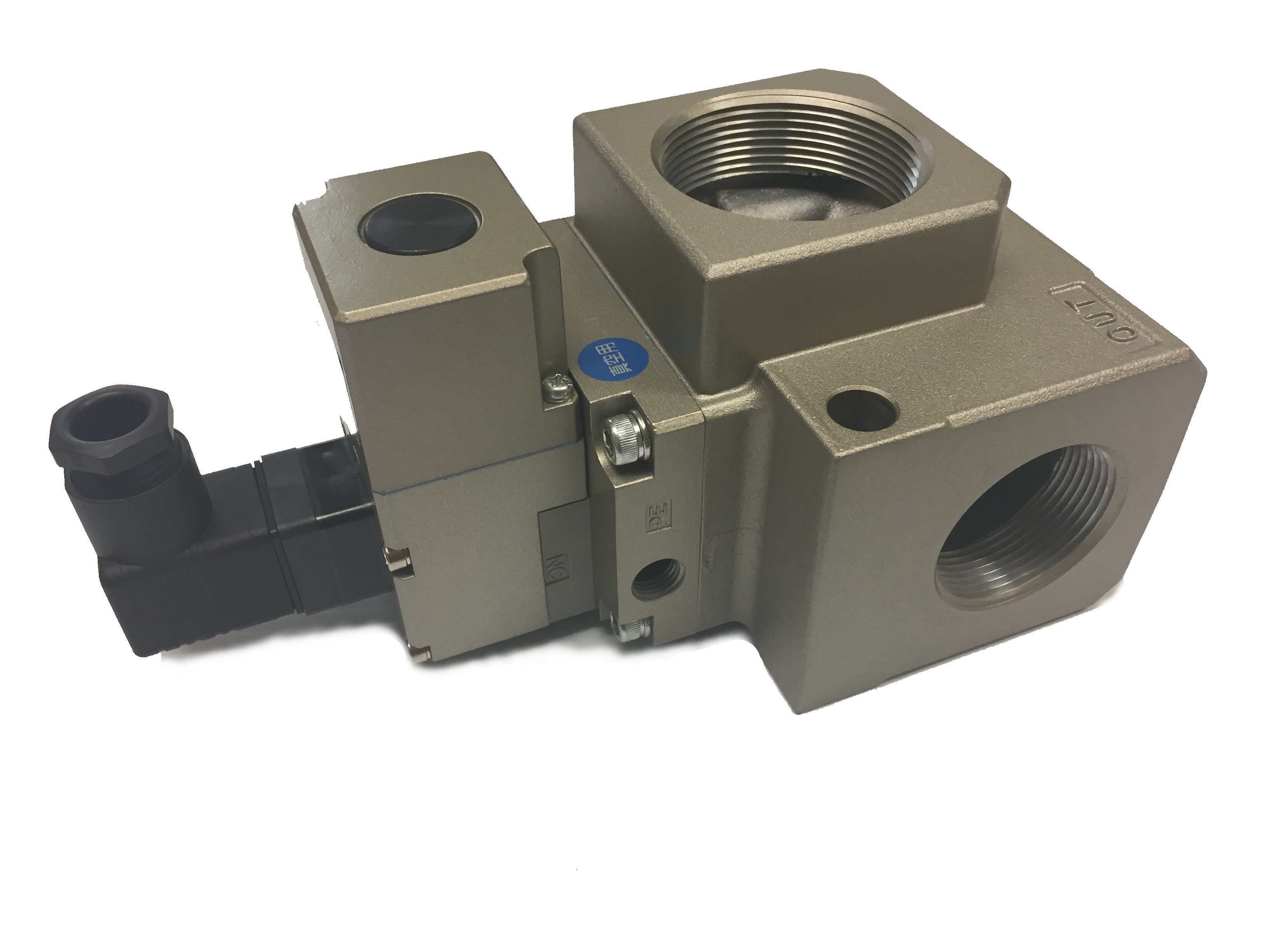

We carry high quality replacement vacuum valves that offer high flow capacity and reduced power consumption. May be used as either a selector valve, or a divider valve. For use in vacuum applications or under low pressure. Available in a normally closed or normally open styles. Large flow capacity, small exhaust resistance Easy conversion to N.C. or N.O. Free mounting orientation For pricing and availability please contact our sales team. ...

We carry high quality replacement vacuum valves that offer high flow capacity and reduced power consumption. May be used as either a selector valve, or a divider valve. For use in vacuum applications or under low pressure. Available in a normally closed or normally open styles. Large flow capacity, small exhaust resistance Easy conversion to N.C. or N.O. Free mounting orientation For pricing and availability please contact our sales team. ...

Original replacement parts for Becker pumps ONLY. Each set of vanes is packaged and sealed at the factory. ...

We use Becker Vacuum Pumps in all of our products and sell replacements for our customers. An example of a pump we carry is listed below. If you need a different pump or have any questions, please contact us to learn more. The Becker Model SV 300/1 Regenerative Vacuum Pump and Motor (LEFT) is a single stage regenerative vacuum pump with an integrated inlet and discharge silencers, vacuum relief valve, inlet filter and integrally flanged to a 4.8 HP, 208/230/460 volt, 3 phase, 60 Hz, TEFC motor. Capacity 229 SCFM open flow. Maximum pressure 141″ H2O. ...

We sell many sizes of vacuum tanks to replace or upgrade your current tank. When dealing with vacuum forming machines using the industry standard “Pump and Tank” systems, make the tank large enough so that there isn’t too much vacuum loss at the end of the forming cycle (large parts are worse). Then make the pump large enough to recharge the tank quickly to a usable level before the next part is ready to form. When evacuating a tank, the pressure will drop very quickly at first, then get real slow at the very end. If your pump is too <a class="read-more" href="https://sibeautomation.com/parts/vacuum-tanks/">[...] Read More</a> ...