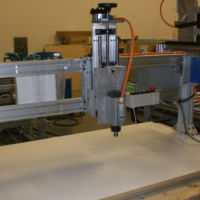

Great machine to trim vacuum formed parts.

The pneumatically driven head retracts 6″ away from the part without losing the depth of cut that is controlled separately.

The frame of the machine is built of heavy-duty structural aluminum extrusion.

The machine is mounted on a base with a working envelope of 48″ x 48″ and the Z-axis will travel 10″.

All linear bearings ride on hardened shafts and are mounted on precision machined plates.

The Z axis is driven by a trapezoidal lead screw.

FIMEC variable speed 1.34 HP SPINDLE MOTOR 0 TO 24000 RPM (speed adjustable on the fly). Driven by an ATC variable speed drive, allowing you to adjust it to best match it to different materials

We provide with each machine a convenient operator pendant.

Each machine is supplied with 3 sizes of R200 collets: ¼”, 3/8″ and ½”, also included are spindle and collets wrenches.

Each machine undergoes a rigorous real-life test.

Machine requires 220 volts, 3 phase, 10 amps, other voltages available

This is built to order machines, current lead time is 3 weeks.

Each one of our machines is covered by a 12-month limited warranty and is backed by a 24/7 technical support.